Posted to News on 8th Dec 2022, 11:12

The future of motion control systems

Efficiency, sustainability, individualisation and of course digitalisation require easily adaptable and future-proof systems from the machine/system builders. Lenze has the answer to these challenges – here we speak to Daniel Lindemann, the company’s head of product management automation systems.

Lindemann starts by explaining the challenges we all face today: “We live in an era where typical innovation cycles are becoming shorter and shorter, but at the same time mechanical engineering is dependent on continuity,” he says. “As a result, ‘time-in-market’ is currently becoming just as important as ‘time-to-market’. By this I mean that it is becoming more important for customers to opt for architectures that remain available in the long term, because they don’t want to have to change their architecture every now and then.

“In software development, the trend is increasingly towards integrated solutions across the chain. This is because modular software is the diffirentiator for the future of engineering. With the Easy System Designer, for example, we are able to guide and support our customers from the first idea to the finished machine. That entire process is digitalised, so the digital twin is no longer a utopia.”

Lenze can play a crucial role in allowing the customer to better play his own competences. Which tools do you use for that?

“The approach via Lenze FAST is a perfect example of our approach. That platform first of all allows the machine to be modularized and to use pre-tested core functions. This reduces the commissioning time and gives the user the freedom to work out his core competence.”

In Lenze FAST, ready-to-use templates ensure shorter development times and gives the user the freedom to work out his core competence

“The second perspective of FAST is the adaptation of existing machines. Wherever possible and useful, the parameterization can be supported or replaced by automatisms from FAST. There are already several modules in our toolbox, such as learning the diameter of a roll in a winding application, learning the probe window for a register check, autotuning for temperature control and drive, identification of inertia and friction, oscillation compensation for stacker cranes, brake test and gravel-in and load detection for lifting applications.

“In addition to the ready-made or pre-designed modules in IEC61131, we also offer a ‘FAST Framework’. This means that, for example, standard machine functions for infrastructure and machine optimisation no longer need to be programmed – they are already available automatically. Such standard mechanisms – such as error handling – must be harmonised across the entire product range of the system provider and must also allow for external integration. With the toolbox and the FAST framework, we therefore have the perfect form of connection and harmonisation of OT and IT. Technology modules such as these in FAST solve standard functions of mechatronic elements, but let us be clear that the specific knowledge of the user also remains with the user.”

The IT/OT world differentiates itself more and more in industry. What is here the crucial factor for machine builders?

“Companies today need to think thoroughly about their software architecture to differentiate themselves. Opt for a platform that grows with your business, with a rich and mature application toolbox. Automated services from our FAST Framework allow the software team to focus on essential tasks. With FAST, you are prepared with a software architecture and automated services. Choosing FAST shortens software development time, increases innovation speed and reduces software development and lifecycle costs.”

So digitalisation is no longer a buzzword? What is the role of standardisation? Is Lenze sufficiently open to other players?

“We embrace standards in engineering like IEC 61131, PLCopen and OPC/UA. For customers, this approach ensures that they can also integrate components from other providers. So there is no golden cage with us.”

What are the future building blocks in the Lenze portfolio around motion control?

“In the future it will be even more crucial for an automation provider to bring tomorrow’s functions to market with the necessary agility and at the same time to ensure compatibility. With our open automation system we are already solving the complex challenges of tomorrow today.

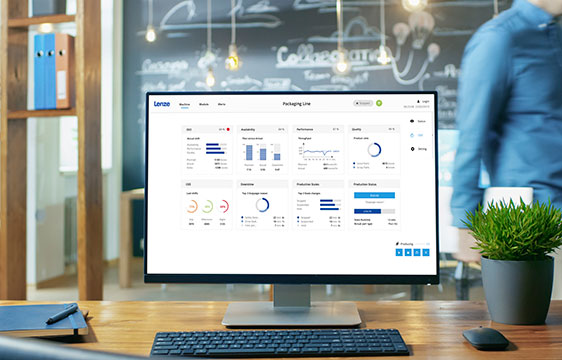

A good example is the Nupano platform we recently introduced to connect the OT with the IT environment. Still the right fundament is to build the right building block layers in the OT to use the right information in the IT environment.”

Want the latest machine building news straight to your inbox? Become a MachineBuilding member for free today >>