Posted to News on 7th May 2021, 09:15

The path to faster development of industrial enclosures

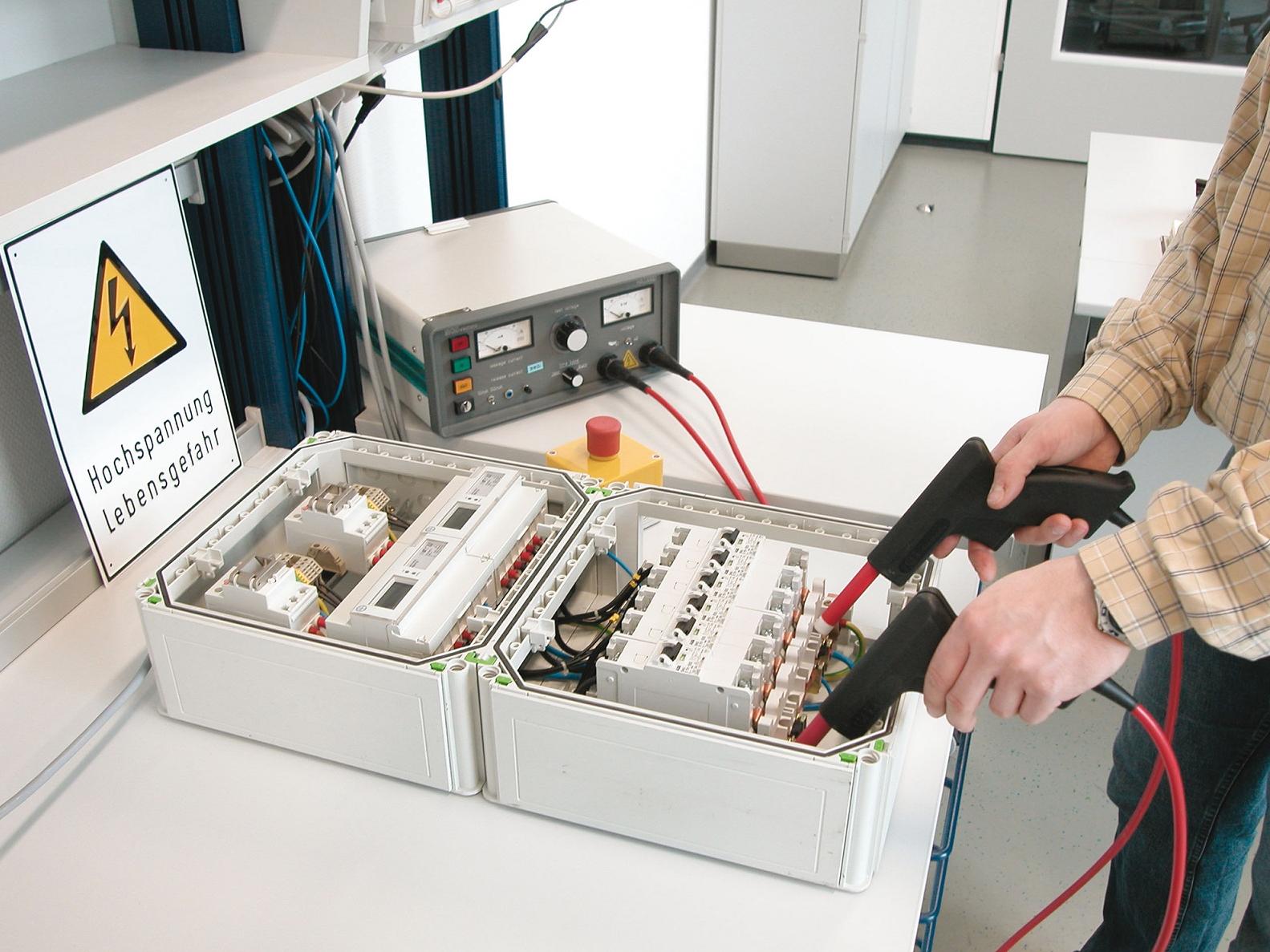

Testing to recognised standards ensures enclosures are up to the task

For product development or bespoke enclosures, testing can delay projects, unless a fast turnaround – still meeting exacting standards – can be achieved. In this article, Chris Lloyd, managing director at Spelsberg UK, explains the benefits of in-house testing to enclosure specifiers…

“Whether an industrial enclosure is protecting a fire safety circuit or maintaining production at a factory, its structural integrity is of paramount importance.

Assurance that an enclosure can meet required performance comes down to testing and the most significant organisations that govern and issue standards for industrial enclosure safety and conformance are VDE and UL.

The German VDE organisation, combined with DIN, the German Institute for Standardisation, issue the German edition of the European standards, referenced as DIN EN.

Meanwhile UL is an American-based safety standard that certifies products as compliant to US standards with cUL covering Canadian testing. VDE and UL marking not only signifies a durable, reliable enclosure, but also means worldwide standards recognition.

Internationally recognised standards

All reputable industrial vendors attain internationally recognised standards for safety and conformance. However, Spelsberg is virtually unique amongst enclosure manufacturers by hosting its own in-house approved test facility that is authorised to certify its enclosures to UL and VDE/DIN EN standards. To ensure full compliance is maintained, the lab is audited by both organisations on an annual basis.

Spelsberg’s in-house lab tests and certifies enclosures for all industrial ratings required for the most demanding applications, from electrical insulation to standards assuring protection against ingress, impact and temperature. Specific tests, such as fireproofing for the Lifeline WKE enclosures, are also carried out in-house at the Spelsberg lab.

While confirming that high levels of enclosure protection and safety are achieved, the advantage of the on-site VDE and UL certified test laboratory is speed of new product development. New products are created on a near continual cycle, frequently based on specific customer requirements to meet the needs of a particular application.

All variants have to be tested

Whether the new product is an update to an existing enclosure model, such as a new size or a housing with alternative pre-assembled fixtures, or a new model that delivers a new solution to a customer challenge, all enclosure variants have to be tested.

Sending the enclosures away for testing takes time and for the customer, this can mean a typical minimum wait of several weeks to several months for completion of the approval process, depending on the type of test. The benefit of in-house testing means that a new enclosure can be quickly brought to market to meet the project deadline, instead of having to specify a less suitable but nonetheless available housing.

For customers that require tailor-made enclosures, the need for a faster testing and approval process is even more important. Spelsberg’s combined knowledge of enclosure manufacture and testing means a bespoke design that will satisfy test requirements, meaning a greater likelihood of achieving certification first time.

Quicker time to market

Together with the faster approval process provided by onsite testing and certification, this achieves a much quicker time to market. For high-volume OEMs, this can make or break a commercial success by ensuring a market first is achieved; likewise, for one-off, high value projects, quick delivery of the enclosure can mean timely introduction or a delay of the whole project.

Of course, in-house testing also means a lower product price, whether for standard products or bespoke designs, as investment in the facility and high product throughput enables Spelsberg to pass on the cost saving. Even if timescale isn’t a critical factor, next time you specify an enclosure, checking that the manufacturer provides on-site testing can help reduce your project cost.”

Want the latest machine building news straight to your inbox? Become a MachineBuilding member for free today >>

Unit 1B Queensway Business Park

Hadley Park West

TF1 6AL

UNITED KINGDOM

+44 (0)1952 605849