Posted to News on 5th Feb 2021, 09:30

Thinking smart when inline testing

How to reduce downtime, minimise rejection rates, and contribute to lower production costs and improved quality control

A key component of most systems are sensors and the continuing advances in sensor technology is helping to provide simpler alternatives for checking a large number of process steps quickly and easily, without the need for expensive, complex systems.

A good example of this is the OXM200 sensor developed by sensing and instrumentation specialists BAUMER, which represents a ‘smart’ multi-profile sensor, ideally suited to inspection and measuring applications. It delivers an almost unlimited operating range, providing users with ultra-efficient inline checks and multi-dimensional control of their manufacturing and processing systems,

This compact, all-in-one, lightweight and calibrated sensor can be quickly installed for immediate use and easily adjusted thanks to an integrated web-browser, without the need for external software. Also, it’s Power-over-Ethernet (POE) functionality means the sensor can be used with a single cable.

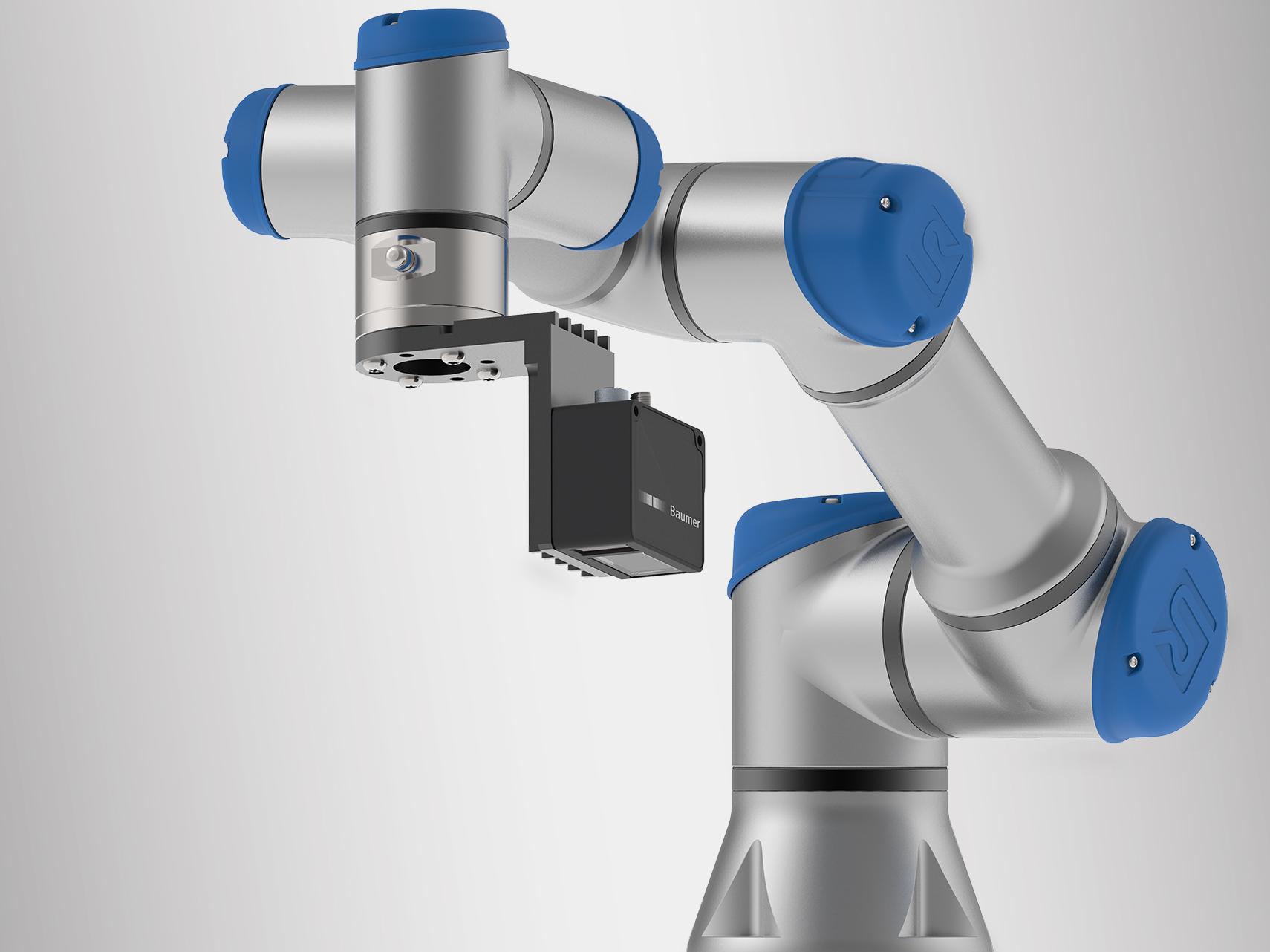

It is designed for integration into image processing systems projecting a laser line onto the object to be inspected. The projected light is reflected from the object and imaged on the integrated camera inside the sensor, which provides a two-dimensional profile of the objects surface. With predefined integrated measurement tools, dimensions of objects along the laser line (X-Y) can be measured and inspected. This allows extensive profile analysis for testing and inspection tasks for applications, such as: height checks of assembly parts, collision checks in assembly, as well as control and positioning tasks in robotics, including the position control of feed parts for pick-and-place or gap checks in car body construction.

Up to seven measurement values can be freely configured with graphical support and, in addition to these integrated functions, OXM200 sensors offer the possibility of linking measuring tools to perform even more versatile analyses. For example, even inspecting items on a conveyor belt with varying positions can be easily and reliably performed, states the company, thanks to position tracking. Another advantage is the live ‘visualisation’ of the measuring tasks in the web interface and settings in the sensor can be directly checked, adjusted and optimised.

Easy integration into automation systems is said to be possible, courtesy of a wide selection of protocols, including: PROFINET, Modbus TCP, UDP, IO-Link, analogue and switching outputs. Direct connection to IT systems and cloud integration with OPC UA, in addition to image processing systems with an SDK (profile data via UDP streaming), is also possible.

Along with the pure profile measurement function, OXM200 sensors offer “easy access to secondary data such as temperature, or operating hours”. All these benefits add up to overall process optimisation for increasing plant effectiveness.

For more information, click here

Want the latest machine building news straight to your inbox? Become a MachineBuilding member for free today >>

33/36 Shrivenham Hundred Business Park, Majors Road

Watchfield

SN6 8TZ

UNITED KINGDOM

+44 (0)1793 783839