Posted to News on 26th Sep 2022, 13:00

Toothed belt drive actuators are compact and flexible

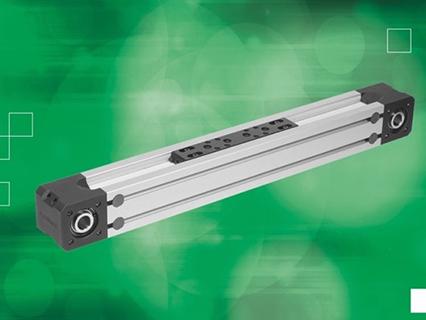

The precise linear actuators from Norelem represent a standard solution available from stock to automate linear movements with ease. A toothed belt drive ensures smooth and synchronous transmission even of heavy and constant loads.

Suitable for use in production, assembly, packaging, logistics, and storage lines or on special industrial machines, the linear actuators, sometimes also referred to as linear axes, with toothed belt drive and profile rail guide offer customers many advantages. They are compact and light, but at the same time convince with very high rigidity. The toothed belt drive ensures a smooth, synchronous drive.

“Toothed belt drives are used in positioning drives, among other things, because they work reproducibly due to the positive coupling,” explains Marcus Schneck, CEO of Norelem. “In addition, they can be designed to be largely backlash-free. In this case, the toothed belt drive is used as an actuator.”

Thanks to the sealed bearings, this results in low maintenance for Norelem’s linear actuators. The belts themselves are easily accessible, so users can easily adjust the tension or replace them if necessary. The standard stroke lengths are up to 1960 mm, but on request the linear actuators are also available in special lengths up to 4000 mm.

The base body consists of a self-supporting extruded aluminium profile with integrated profile rail guide. It is a standard profile of series I with the dimensions 60 x 60 mm or 80 x 80 mm. The rail system can absorb the highest forces from all directions, is low-wearing and offers optimum running when moving large masses. There are grooves on the outer sides of the aluminium profile for easy and safe mounting and for attaching accessories. The groove width is 6 or 8 mm.

Due to the symmetrical design, the linear axis allows motors and gears to be mounted on all four sides of the bearing housings. The aluminium slide of the linear guide has four threaded holes for mounting additional elements. Additional centring holes enable precise mounting.

Toothed belts reinforced with steel tension members enable high power transmission and, at the same time, high positioning accuracy. The toothed belt runs in guide grooves on the top of the aluminium profile and thus protects all parts in the profile from dirt.

“In combination with toothed belt pulleys, toothed belts from Norelem are used everywhere in mechanical engineering, the automation industry and in the trades,” explains Schneck. “They show their advantages where the transmission of large forces, high acceleration, exact positioning and synchronisation consistency are required.” Their reliability and low maintenance requirements, smooth running and high energy efficiency make timing belt drives a preferred drive medium. Norelem not only stocks a wide set of standard sizes, but also has timing belts available by the metre.

In combination with timing belt pulleys, timing belts form a compact drive with high power density and excellent efficiency. They are low-maintenance and low-noise, resistant to a wide range of environmental influences and, if correctly dimensioned, extremely durable. “Endless timing belts are generally used for drive solutions,” Schneck elaborates. “They ensure a consistently high-performance profile as well as length stability.”

The yard goods, which are also available from Norelem, are mainly used to convert the rotary movement of the timing belt pulley into a linear movement. In this case, the open ends are attached to the moving slides by means of clamping plates. If the yard goods are welded together to form an endless belt, the strength values are reduced by around 50 % because the tension members are separated at the welding point. They are therefore not suitable for applications that require precision and the transmission of high as well as uniform forces.

The yard goods are manufactured in standard roll lengths of 100 metres and can be supplied in any desired length. The temperature range for use of the belts is from -30 °C to +100 °C. The belts have a very good chemical resistance, for example to grease and oil.

Different materials and profiles

Toothed belts are available from Norelem in different materials and profiles. Profiles T and AT are made of polyurethane (PU) with a steel tension member. In the HTD profile, the belt tooth and back are made of chloroprene rubber (CR), the tension cords in the timing belt are made of glass cord. The tooth cover fabric is made of polyamide.

Toothed pulleys are made of high-quality aluminium or steel, depending on the design, with the lowest tolerances. The pulleys are centred or pre-drilled. Fitting bores and keyways can be inserted subsequently if required. In addition, Norelem offers toothed shafts with which own toothed pulleys and clamping plates can be manufactured for fastening the open toothed belts.

For the linear actuators with toothed belt drive, Norelem offers numerous accessory options. Slot tables, for example, allow an infinite number of mounting options on the guide carriage due to the profile slots. In addition, motor mounting kits are available from Norelem, which provide a simple and economical solution for connecting electric motors. Protective caps effectively protect open axis ends from dust, while aluminium profiles allow easy connection of linear actuators. Synchronisation kits allow the synchronisation of two linear actuators mounted in parallel. Last but not least, Norelem stocks inductive proximity switches that can be mounted and screwed in from above.