Posted to News on 1st Nov 2006, 21:49

Torque transducer used to evaluate motors

The University of Texas is working on a new test bed that will radically improve evaluation of motors for demanding applications. At the heart of the test bed is a Torqsense transducer from Sensor Technology.

Getting the right motor for a demanding application is not exactly a hit-and-miss affair, but the performance curves supplied by the manufacturer can only tell you so much. Beyond that, real-world performance evaluation is needed, and this is where modern test beds come in, offering the ability to test actuators under a static load (such as a brake) and providing an important indicator of long-term performance and reliability.

Even then, however, the overall picture is limited. Recognising the need for a test architecture that would look at all possible operating conditions, the Robotics Research Group (RRG) at the University of Texas set out to design a test bed that would measure and record an array of physical properties during both dynamic and non-linear load testing.

The result of the Group's work is the Nonlinear Test Bed for Actuators

(NBTA) which is able to simulate real-world operation under both linear and non-linear loads.

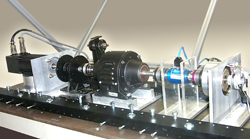

Test bed layout

Flexible enough to accommodate a whole range of prime movers, the test bed comprises a load motor, a four-bar linkage, a brake/clutch and a torque sensor. Each component is linked to the next via a bellows coupling, with a further bellows coupling used to connect the torque sensor to the motor under test. All components are held rigidly against a variety of load profiles by long steel rails, which are secured to the test bed so as to resist horizontal and vertical forces in order that the testing provides an accurate picture of motor performance. Supporting blocks for the various mechanical components are height adjustable to accept a range of different prime movers.

In operation, the load motor provides the dynamic test by generating various types of load, while the four-bar linkage creates the non-linear periodic load. The load profiles can be readily defined to simulate real-world conditions for the test motor. An encoder is connected to the motor to provide position, velocity and acceleration data, while the torque sensor measures the torque between the load motor and the test motor.

With the torque sensor holding the key both to evaluating the performance of the test motor and enabling torque control of the load motor, the Group recognised that selection of this critical product was vital to the success of the test bed. The torque sensor needed to have a torque, speed range and torsional stiffness higher than the operational range of the test motor. And because the test bed had to handle a range of different motors with different torque-speed curves, the torque sensor also had to be extremely accurate.

Measuring rotary torque has historically been difficult and expensive because traditional techniques are invasive to the mechanical systems being measured. So for an affordable and practical torque sensor that would meet these demanding requirements, the Robotics Research Group turned to Sensor Technology.

Patented application of SAW technology

Based in Banbury in the heart of Oxfordshire, UK, Sensor Technology has developed a range of torque sensors based on surface acoustic wave (SAW) technology. The Torqsense transducers use SAW technology in a novel and patented way to overcome the problems associated with traditional torque sensors, delivering high performance while remaining inexpensive.

The SAW-based transducer is essentially a 'frequency dependent' strain gauge that measures the change in resonant frequency caused by an applied shaft strain. Two SAW devices embedded on a shaft form part of a high-frequency oscillator circuit. When the shaft is twisted, the resulting deformation of the substrate creates a frequency difference between two embedded SAW devices. The two frequencies produced by the SAW devices are mixed together to produce difference and sum signals. The difference signal is a measure of the induced strain due to the twisting moment and, from this, the torque can be derived.

The Torqsense transducers built on SAW technology are designed to operate direct from a PLC or a PC, thereby removing the need for conventional instrumentation, and they also interface with standard DPMs. Torqsense transducers require minimal shaft length and have low inertia, no physical contact between shaft and housing, wide bandwidth, high resolution, high accuracy and excellent magnetic/RF noise immunity.

Evaluation of the NTBA test bed has only just begun, with the Robotics Research Group currently focusing their efforts on assessing permanent magnet synchronous motors - a first choice in many robotics applications, since they have distinct advantages over conventional DC motors. Permanent magnet (PM) synchronous motors are also an attractive choice for heavy-duty applications because a large output can be obtained during high acceleration and deceleration rates. For the purposes of evaluating the test bed, permanent magnet synchronous motors have the advantage of high-torque, low-speed characteristics, enabling the researchers to give the test bed a thorough workout.

But the hope is that the test bed will soon be testing a whole range of prime movers, assessing these motors' characteristics for demanding applications as diverse as electric vehicles or submarine trim tab actuation.

Use the form on this page to request a callback or more information about TorqSense.

Apollo Park, Ironstone Lane

Wroxton

OX15 6AY

UNITED KINGDOM

+44 (0)1869 238400