Posted to News on 8th Dec 2022, 12:30

Traceability 4.0: The fundamental element of global manufacturing

Omron has produced a whitepaper looking to developments in traceability, highlighting how so called ‘Traceability 4.0’ connects digital and physical technology to optimise and improve yield.

The manufacturing industry is moving at a fast pace and it is hard for producers to keep up with the continuous need for change caused by new regulations, counterfeit operations and individualised consumer needs.

Traceability is vital for protecting your brand and it can also provide valuable information for improving your processes. We use our vast experience in track, trace and control to help manufacturers build robust systems that protect and improve processes today and tomorrow.

All levels of traceability are critical to the success of manufacturing. In fact, most industries will see and use all levels in their plants or facilities. One phase is not ‘better’ than the other; the full complement is their strength. The evolution of traceability is the direct result of business needs and is crucial in the hyper-competitive world of global manufacturing and more recently in the food and beverage industry, authenticity is essential. Consumers need to know that the foods they’re purchasing consist of the things listed on their labels, as food allergies and expired foods can cause serious illness and possibly death.

While similar in many ways to Industry 4.0, Traceability 4.0, and all its phases, is different in several ways. Timing and availability is one key difference. When speaking of Industry 4.0, in some cases there are decades between advancements, and generally they are not being developed, or used, at the same time. Many steps of this progression were sequential.

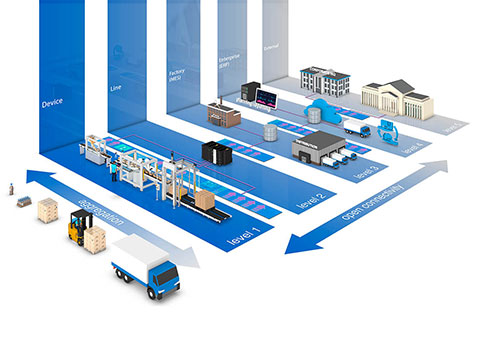

The concepts and technologies of traceability began just 40 years ago, and are actively building upon each other and are being used concurrently, for both bettering production and sparking new technology developments. The other large difference we see is the focus of Industry 4.0 compared to that of Traceability 4.0. They both focus on improving and connecting digital and physical technologies to optimise manufacturing and improve yield. Traceability, however, brings an additive dimension – ensuring quality components and end products. It is this laser sharp focus on credibility and brand protection that true traceability can deliver.

Omron’s vision has always included the working relationship between people and robots, which it terms ‘Highly Diverse Traceability’: tracing the fusion line of people, robots, machines and devices without interruption.

Traceability 1.0 generates enhanced efficiency and productivity. Traceability 2.0 helps to optimise summary inventory management, product quality, safety, and regulatory compliance. Traceability 3.0 is essential to anti-counterfeiting programs and to product and component compatibility optimisation. Traceability 4.0 achieves the 4 Ms (Material, Machine, Man, Method), optimising overall manufacturing effectiveness and brand protection, and also introduces AI into certain elements of process control.

Crucially, the four phases of traceability have not cannibalised one another. They have in fact been accretive, and will continue to build upon each other. Transactional efficiency, social needs, supply chain management, and manufacturing optimisation will only become more important in the coming decades.

Traceability 1.0 is still used extensively in manufacturing and retail environments and many manufacturers continue to refine their Traceability 2.0 programs. Manufacturers will continue to develop Traceability 3.0 programs to optimise supply chain management and product precision and performance. As a culmination of each of these phases, Traceability 4.0 is leading manufacturers to the forefront of traceability and brand protection.

Omron is well positioned to provide significant and innovative value to customers in this space. Our global portfolio of traceability products and solutions is integrated, intelligent, and interactive. Our core “MVRC” offerings (mark-verify-read-communicate) include barcode readers, ISO-compliant barcode verifiers, laser markers, and RFID. Omron has a complete automation platform featuring programmable logic controllers, motion controllers, machine vision systems, safety technology, and robotics to facilitate a complete traceability solution for data management, inspection, and material handling. Our IoT enabled devices communicate data seamlessly with each other and across multiple data layers within an organisation (MES or ERP). This data connectivity enables analysis for continual improvements to be realised. We were present at the beginning of traceability’s evolution and we will continue to drive that evolution forward.

Recognising how traceability has evolved due to the implementation of technology, Omron has produced a whitepaper that explores the evolution of traceability and explains why the latest phase, Traceability 4.0, is not just about tracking products throughout the supply chain but also optimising productivity, quality and brand reputation within the manufacturing operation by tying product to process parameters. You can download the whitepaper here.

Want the latest machine building news straight to your inbox? Become a MachineBuilding member for free today >>