Posted to News on 1st Sep 2022, 16:19

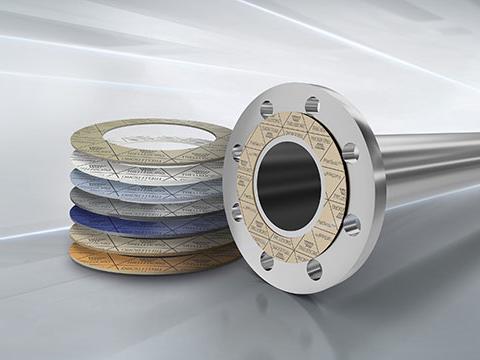

Trelleborg launches new flat gasket range

Trelleborg Sealing Solutions launches HMF FlatSeal, a new range of flat gasket materials for effective static sealing in low and high-temperature applications.

The range includes specialist materials for use with harsh chemicals and mediums in aerospace, automotive, oil and gas, food and beverage, chemical processing and pharmaceutical industries.

Marco Schildknecht, chemical and processing segment manager for Europe at Trelleborg Sealing Solutions, says: “Our new range of flat gaskets is best-in-class and designed to fulfil the requirements of a wide range of applications, to complement our existing market-leading sealing solutions. The HMF FlatSeal range includes 20 materials, from a standard material for low to moderate pressure and temperature applications to engineered solutions for high-pressure, high-temperature environments, and even specialist materials for food contact applications with FDA and other conformities.

“Through collaboration with our customers, we fine-tune the material selection and the gasket geometry to optimise the overall sealing system. Complex flat gasket geometries are easily created, with the option to include metal inlays or inserts in graphite gaskets. This provides enhanced strength and increased pressure to temperature ratio for harsh environments.”

Trelleborg’s new flat gasket range includes materials that are engineered to comply with food contact material regulations globally, including US Food and Drug Administration (FDA) regulations, European Food Contact Regulations (EC 1935/2004), and Chinese food safety standards (GB).

To enable the easy identification of gaskets, select materials are equipped with Trelleborg’s FlatSeal Code Technology. Each production batch can be identified via a unique ID, which enables full traceability from the material batch to the cut gasket. This technology provides clear information even after the gasket has been punched and cut to shape, regardless of the temperature, exposure to media, or the length of time in operation.

The FlatSeal Selector tool, available on Trelleborg’s website, offers users the ability to select a material based on individual operating conditions and data. Users can choose from a list of media and materials, see temperate and pressure limitations, and select the ideal gasket solution for their application. The tool includes a design configurator with recommendations to support optimised gasket design.

Pegasus House

1 Cranbrook Way

B90 4GT

UNITED KINGDOM