Posted to News on 22nd Aug 2013, 16:52

Two new e-spool energy chain variants from igus

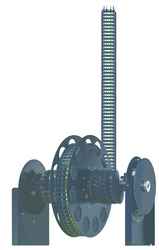

igus UK is launching two new variants of its innovative and compact e-spool energy chain. The new heavy duty (HD) and motor flange versions are more powerful, enabling users to more easily retract and guide cables and e-spool allows engineers to save space thanks to its small footprint. Quick and easy to install, e-spool is flexible, providing cables reliably in any direction for travel up to 14m.

Developed in response to customer demand for support with retracting higher loads, igus now offers three different e-spool products, depending on the pull out direction and load. The standard e-spool features a simple spring mechanism for retracting the chain and is suitable for most applications and for any direction. However, vertical applications require a higher retraction force, and so the HD version has been designed with an extra tough spring providing stronger retraction. Finally, the motor version with motor flange is available for use with a motor to allow higher filling loads and movements in any direction.

e-spool is the only cabling system that guides all media types such as data, compressed air and liquids, flexibly and with minimum space in one system. It combines two different energy chains in an innovative way. A standard igus e-chain is routed via a spool and an igus twisterband connects the spool with the shaft bracket, which serves as the interface to the permanently installed cables. Instead of featuring costly sliding contacts, which are typically featured in classic cable drums, the cables can be connected without interruption and can be replaced or modified at any time.

All three e-spool versions are available in different extension lengths (0-4, 4-7 and 7-14m) and with one or two twisterbands depending on the cable capacity required. The maximum spooling speed is approximately 1m/s and the twisterband enables cables with up to 17mm to be housed.

Justin Leonard, director at igus UK, says: "e-spool is a next generation cable management system and we're pleased to introduce these new variants which offer customers more choice to best suit their application. Users can now benefit from a robust and flexible system that provides reliable operation for a wide range of lifting applications."

It is suitable for many lifting applications where users are looking for space-saving energy chains, such as lifting platforms, cherry pickers, sorting lines, mobile cranes, platform applications, assembly or process cranes with grippers, or lighting rigs in the theatre industry. In addition, users can save space associated with storing the chain, as it has a smaller footprint than traditional zig zag chains used in these applications.

As with all igus e-chains, e-spool is reliable and the plastic energy chain is easy to install and use. Users can simply press the cables into the chain from the outside, without the chain links being opened and closed.

For more information about the e-spool energy chain, please visit the website at www.igus.co.uk/e-spool.

Want the latest machine building news straight to your inbox? Become a MachineBuilding member for free today >>