Posted to News on 24th Aug 2023, 11:15

Ultrasonic sensors help get to the ‘meat of it’ on a bin wash-line

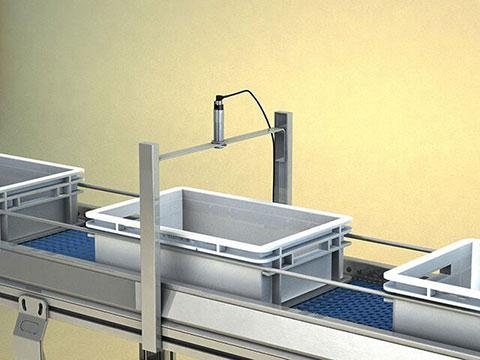

When a meat processing plant operator needed a solution to check that transportation bins had been emptied prior to being sent to an automated wash station, it turned to Contrinex. An ultrasonic sensor mounted above a conveyor looks down into the bins and diverts contaminated bins from proceeding to the wash station.

Inside industrial meat-processing plants it is common for portions of meat to be transported in food-grade plastic bins. Before these plastic bins can be washed in an automated wash station, a check is needed that there are no pieces of meat left in the bin. If any pieces of meat are allowed to remain in the tray and enter the wash station, they can accumulate in the washing machine, causing blockages and breakdowns.

To prevent this, a sensor system must reliably detect the presence of meat residues in the bins as they travel along the conveyor. The sensor needs to differentiate between small trivial residues and larger contamination, diverting the contaminated bins before they can enter the washing station.

The previous mechanical system which used spring-loaded wand actuators in contact with the box was unreliable and required frequent, time-consuming cleaning and adjustment. Breakdowns and interruptions to the washing process could limit the availability of clean transportation bins and impact the plant’s overall productivity.

Contrinex ultrasonic sensors are ideal for presence and level-sensing applications being available in both reflex and diffuse sensing technologies. For this application, an M30, metal-bodied, IP65-rated, diffuse sensor with a 20 to 130cm operating range was selected.

Ultrasonic sensors are ideal for this application because their detection is independent of the target’s colour, shape, material or surface structure. They reliably detect all items above a set height threshold, even if it is transparent, for example, plastic packaging. The vibration of the sensing face of the ultrasonic sensor, also contributes to keeping itself clean or shedding liquid contamination, in much the same way as the ultrasonic parking sensors in a car’s bumper are often cleaner than the rest of the bumper surrounding them.

The ultrasonic sensor is mounted above the conveyor, looking down into the bins as they travel past it, towards a wash machine. The sensor checks for residues, rejecting any contaminated bins using an existing mechanical diverter to shunt the box to a separate conveyor for manual emptying.

Being able to mount the sensor at some distance above the conveyor enables easier cleaning and the system has proved ideal, requiring little or no regular maintenance.

Want the latest machine building news straight to your inbox? Become a MachineBuilding member for free today >>