Posted to News on 7th May 2021, 09:27

Unveiled: new EMC filter for regenerative applications

Protection from overheating provides extra safety layer for machine builders

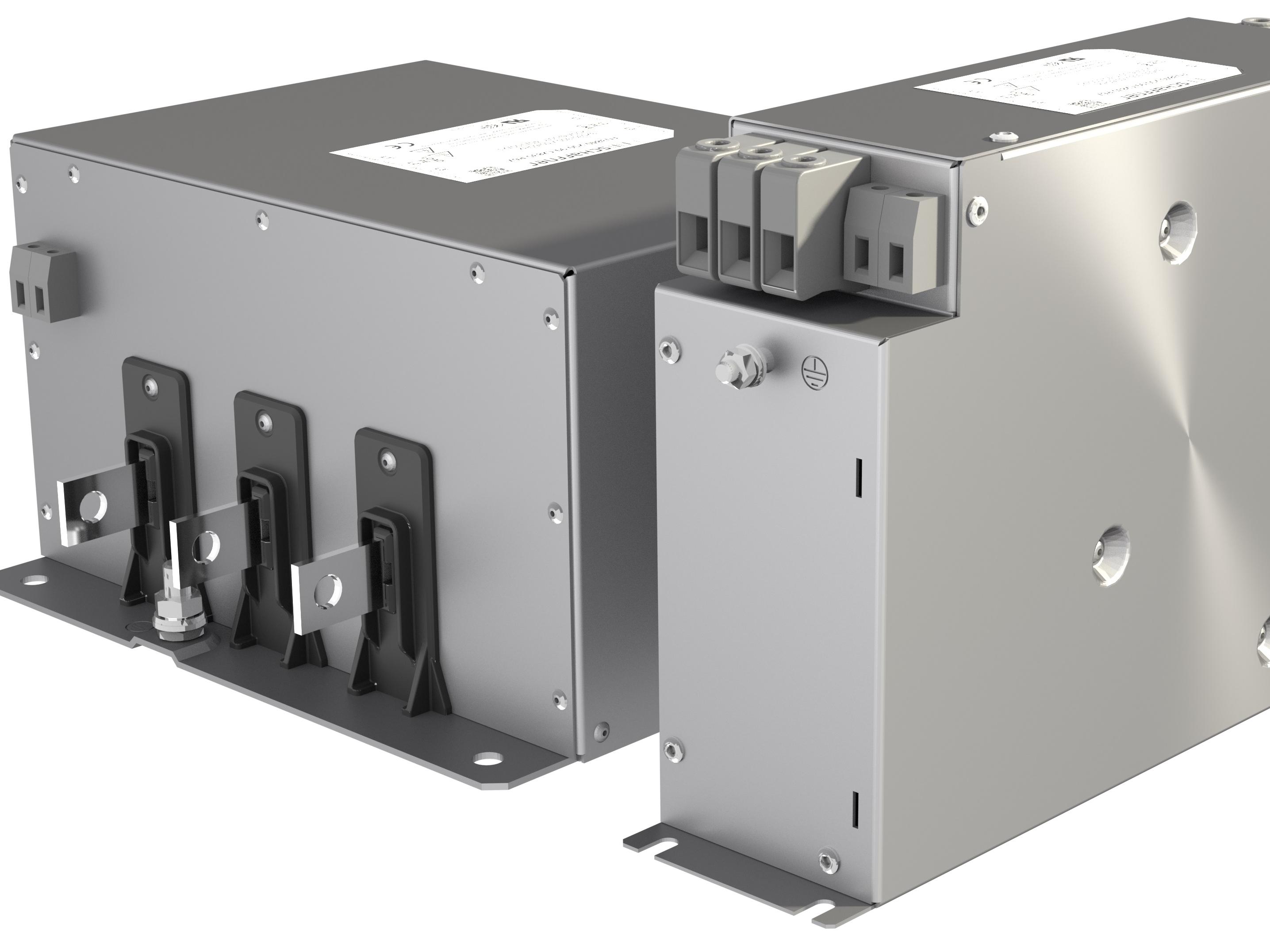

Schaffner has unveiled its new FN3840 filter for use in Active Infeed Converter (AIC) or Active Front End (AFE) applications where energy is fed back to the power grid.

This process reduces energy costs in larger factories or can be used to reduce losses and excess heat in converters. When the semiconductors of the converters are switching directly towards the mains power network, they create a high voltage and current ripple. “The inclusion of an LCL-filter, such as the recently launched FN3840, can further reduce this effect and improve power quality.”

Innovative filter topology

Schaffner continues: “FN3840 series of filters provide state-of-the-art EMI attenuation, based on an innovative filter topology, and help to ensure compliance with Class C2 or even C1 limits. Applications include regenerative drives in combination with LCL filters, active infeed converter (AIC), active front end (AFE) variable frequency drives (VFD), three-phase variable speed drives (VSD) and power drive systems (PDS), renewable energy, machine tool and machinery equipment, process automation equipment.”

In systems where compliance to EMC regulations at frequencies above 150kHz need to be considered, not every EMC filter can be connected in-line with an LCL filter. The inductive components of an LCL-filter can resonate with the capacitors of the EMC-filter and vice versa. To overcome those effects and to avoid damage of the drive, a careful design of the EMC-filter circuit is mandatory.

The new Schaffner FN3840 has been fully tested, adds Schaffner, and may be combined with a Schaffner FN6840 LCL-filter in an AIC/AFE application.

The FN3840 is fitted with an onboard temperature monitor to provide protection from overheating. The switch will open at the critical temperatures of 180°C; or 150°C for busbar versions. This provides an extra safety layer for machine builders. In the event of an open temperature switch the Active Infeed Converter can react and reduce or switch off power.

Added appeal for machine builders

The new Schaffner FN3840 is supplied in a slim book-style shape, allowing convenient and space-saving installation next to inverters, converters or motor drives. Connection is via solid safety connector blocks and versions are available with low leakage current.

The new FN3840 filters offer very high saturation performance, combined with high EMI performance, fulfilling the requirements in IEC/EN 61800-5-1 for electric strength, clearance and creepage, IEC/EN 60204-1 for insulation resistance, electric strength, clearance and creepage, and the requirements in IEC/EN 62477-1.

Want the latest machine building news straight to your inbox? Become a MachineBuilding member for free today >>