Posted to News on 3rd Jan 2008, 20:27

Valve terminal enables standardisation on fewer components

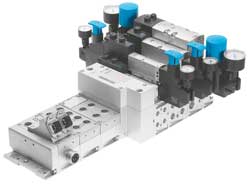

Festo is launching a highly configurable valve terminal that is said to offer major cost-saving advantages to automation designers and builders, who can now standardise on fewer components to reduce their spares inventory and minimise service costs. The new VTSA valve terminal can accommodate up to 32 ISO standard 18mm, 26mm and 42mm valves, and permits any combination of these valves to be mounted on the same manifold.

Festo's VTSA valve terminal is supplied as a fully assembled and pre-tested unit, enabling users to effectively replace an entire control panel via a single order. The valve terminal is fully compliant with the new ISO 15407-2 standard, which defines the mounting interface and electrical connections for five-port pneumatic directional control valves and was developed to harmonise the platform for VDMA standard 01 and 02 sized valves, which are now known as 26mm and 18mm valves.

VTSA valve terminals feature robust, metal sub-base modules, and employ generously proportioned air ducts to maximise air flow. Festo offers a wide range of compatible 5/3, 5/2 and dual 3/2 valves, all of which have an operating pressure range of -0.9 to 10bar. The valves are available in 18mm, 26mm and 42mm sizes, with respective flow rates of 550, 1100 and 1500 litres/minute. All three valve series offer a choice of 24V DC and 110V AC solenoids, and can be configured so that their breathing ports vent into the exhaust port instead of to atmosphere, making them suitable for use in clean air environments such as food processing plants.

An innovative feature of the VTSA valve terminal is that it allows the valves to be oriented so that all pneumatic and electrical connections are accessed from one side of the unit. This leads to a very clean installation, which requires less physical space and simplifies servicing. Furthermore, the valves all feature front-panel LEDs and the pressure regulators are equipped with swivelling pressure gauges.

The VTSA valve terminal can have individual electrical connections, multipin connection or can integrate directly with Festo's CPX terminal controller, which is a modular, high-functionality hub with an Ethernet interface and extensive fieldbus protocol support. The controller enables advanced remote diagnostics capabilities to be easily incorporated into factory-wide local area networks, to provide centralised control and monitoring of individual valve performance. Local diagnostics can either be performed using the valves' front panel LEDs, or via Festo's CPX-MMI handheld control unit.