Posted to News on 11th Mar 2021, 09:35

Variable speed drive replacement gets the verdict

Law firm saves money with cost-saving solution

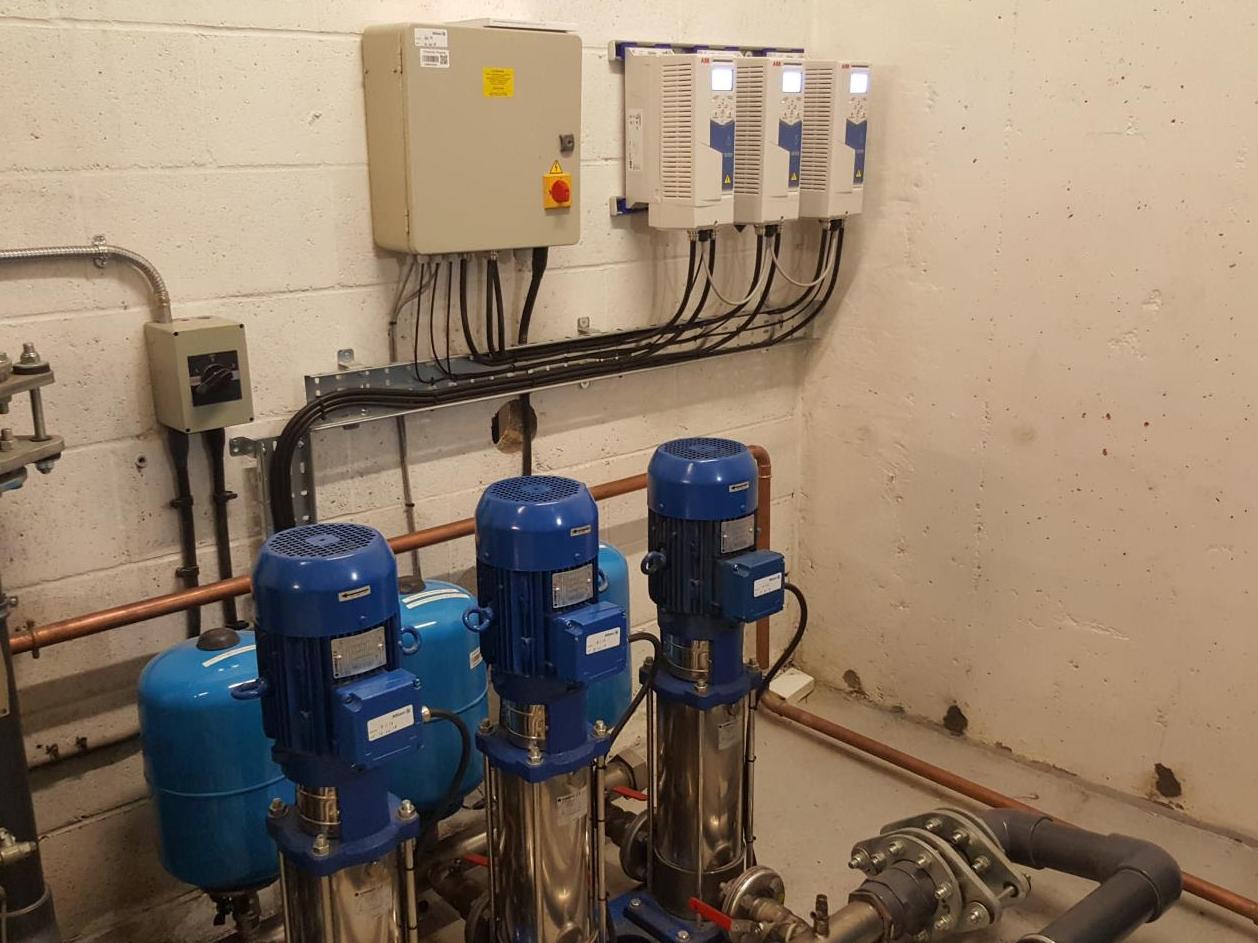

Replacing inverters integrated into OEM-built pump booster sets with externally wall-mounted variable speed drives (VSDs) has saved a building’s clientele more than £20,000 by avoiding exchange of the entire units.

Three pump sets are used at the UK head offices of international law firm Bryan Cave Leighton Paisner (BCLP) to boost cold water flow by maintaining pressure on each of the building’s 12 floors.

Electrical surge

However, during a refurbishment of the building, an electrical surge caused damage to the inverters used within each of the pump sets.

Faced with a costly bill to replace all three pump sets in their entirety, BCLP asked ABB partner Triac Services to seek alternative solutions. Each pump set comprised a 4 kW inverter, motor, pump and an electrical control panel. Investigation revealed that it was only the inverter within each set that had failed.

Costly outlay avoided

By removing each inverter within the pump sets and replacing these with a standalone 4 kW variable speed drive, the cost of new pump sets was avoided. “The ABB VSDs are easy to program,” says Lorimer Colledge of Triac Services. “From the primary settings menu, we selected multi-pump control and then followed the parameter settings to allow automatic PID pressure control. This is based on a 4-20 mA signal from a pressure sensor to each VSD on the three-pump system.”

Furthermore, a one-day installation and commissioning and lower energy use significantly contributed to the payback of the refurbishment. By replacing the inverter with a wall-mounted VSD, the system design is simplified, making maintenance easier and therefore less costly. For instance, the VSD is not subjected to any vibrations or heat dissipation from the pump, unlike the inverter mounted within the pump set. Also, should a leak occur, the VSDs are wall-mounted away from the main pump set, avoiding any water damage.

Efficient switchover

Another benefit of the ABB drive, it is said, is that its built-in intelligent pump control software enables each VSD to communicate with each pump set independently, ensuring an efficient switchover between duty and standby/ assist modes.

The VSDs are programmed to share the operating duties in 12-hour shifts, balancing the workload and helping spread the wear and tear among the three drives, extending the pump set life expectancy.

Colledge continues: “As taps are turned on and off in the building, the VSDs change the speed of the pump motors to maintain the setpoint pressure of 6 bars across the 12 floors. The program is set to automatically select one of the standby drives to provide extra pumping to help the duty drive, as required.”

Comments Dan Cooper, BCLP’s facilities manager for Governor’s House: “The new drives have future-proofed our pumping system. With this standalone solution, if the pump fails, it will be easy to replace it with a standard pump.”

ABB Automation Technologies (Drives and Motors)

3100 Daresbury Park

Daresbury

WA4 4BY

UNITED KINGDOM

44 1925 741 111