Posted to News on 17th Feb 2023, 09:08

Vetipak enjoys the sweet taste of success thanks to robotics

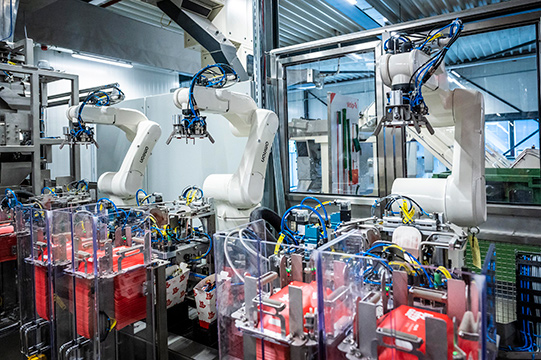

A packaging solution with robotics integrated control from Omron and B Electrical Engineering ensures scalable processes and high-quality contract manufacturing of fast-moving consumer goods (FMCG).

With changing consumer needs and increasing labour scarcity, robotics technologies are a welcome addition to packaging processes. Product life cycles are getting shorter, and manufacturers are looking for more flexibility. A leading contract manufacturer Vetipak responded to these challenges with an innovative automation solution that combines the strengths of people and technology.

Vetipak needed to automate the packaging process for confectionery and luxury cosmetics, whilst ensuring speed, scalability, and quality. They opted for automating three new packaging lines with industrial robotics from Omron, implemented together with Omron Solution Partner B Electrical Engineering.

Vetipak is a Dutch family company, established in 1997, that has since become one of the largest contract manufactures in Europe, working with major food and commodities brands. The company provides innovative and scalable solutions for leading FMCG companies designed specifically to their needs. From automating a highly complicated packaging process that would not be feasible without automation, to ensuring high output or scalability into the future, Vetipak offers its clients a complete production and packaging solution: from design and engineering through to production.

Innovative approach

Mark van der Burgt, chief commercial officer at Vetipak comments: “We recently made a considerable investment to develop our facilities in the Netherlands, including a fully controlled building with temperature, air pressure and humidity control, as well as state-of-the-art automated production lines with robotics technology.”

Thanks to the updated facilities, Vetipak can serve various markets from food, confectionery, pet foods, consumer electronics to personal care products, as well as plans to expand to new markets such as life sciences and health. Ensuring safety and quality, the new facilities enable Vetipak to package a large variety of products that arrive in huge numbers. Vetipak is responsible for ensuring that these products are put in the right packages – such as retail and promotional packages, luxury gift boxes as well as special versions for seasonal promotion or duty-free zones.

Assembling a team of experts

Van der Burgt continues: “To meet the needs of our customers, our new packaging lines needed to be able to handle the volume and the diversity of products being packaged. We also looked for solutions that would be easy to use, working safely and seamlessly together with our staff. The three projects each had their own specific criteria for success.

“In the first project, we needed to create a beautiful gift set, with complicated paper folding, similar to the art of origami. However, if we had carried this out as a manual process, this would have required 15 workers per line, and the project came down to feasibility and cost. Thanks to robotics, we have made it possible to automate the numerous manual handling steps, ensure quality, and made that project feasible with an immediate return on investment.”

“In the other two projects with confectionery packaging, one required a large output and the other needed to be scalable for future needs. For us, and for the business cases, it was important to find a flexible solution that can meet changing consumer demand in terms of different volumes and designs. It is also important for us to be able to repurpose the robots later for other needs. For example, if we would redesign one line, we can use the same robots and technology on the new line,” Van der Burgt concludes.

Vetipak works with a team of software and hardware engineers including long-term partner B Electrical Engineering to build customer-dedicated solutions. Based in Ravels, Belgium, the system integrator specialises in designing control cabinets and providing programmable logic controller (PLC) solutions, as well as vision, motion, sensors, robotics and safety solutions.

Guy Beyens, managing director of B Electrical, says: “When I first learned about the new Robotics Integrated Controller from Omron, I thought it would be a perfect fit to Vetipak’s needs, as not only did it provide the right performance, it was also easy to program. This naturally saves programming time. With one controller, you can achieve seamless, smooth integration of sequence, motion, and robot control, ie, synchronised control of the robots as well as other devices.”

The system integrator and Vetipak’s LAB51 team installed the Omron Viper robots, the Robotics Integrated Controllers, the conveyors, and also built the control cabinet. The Vipers are articulated, 6-axis robots with a maximum payload of 5kg. The Omron NJ501-R Robotics Integrated Controller has been developed for applications that require high-speed processing for machine control, safety, reliability and maintainability. It enables users to increase the speed and accuracy of production, whilst reducing maintenance and time-to-market.

Benefits of the robotics approach

Guy Beyens continues: “The user interface for the new system is very easy and user-friendly. For example, you can make minute adjustments in the movement using the touch panel, that were not possible with other systems. Thanks to the Robotics Integrated Controller, the position of the robot is updated in real time, which is especially important in the gluing process.

“The solution makes it possible to react to environmental factors and adjust as needed, enabling the in-house technicians and operators to be more independent. It is now for example possible to adjust a date on the package, or the gluing position of the robot directly from the touch panel.”

Mark van der Burgt adds: “Having very precise gluing was an additional benefit to the end customer as it improves the quality of the packaging. Luxury products must look good, so they must be glued neatly, completely, and precisely. For the food industry, it's important that everything is safe, so precision is also extremely important there. This is all possible thanks to Omron’s robotics technology.”

Omron’s role included solving any problems that arose; discussing potential solutions; and sharing their technical robotics expertise. Sylvie Van De Weghe, Omron’s sales manager for Belgium and Luxembourg, comments: “We’ve worked closely with B Electrical Engineering for over a decade, and they were the first partner in Europe to test and install the new Robotics Integrated Controller. They are currently expanding and investing in a new building so that they can provide even stronger support for our robotics solutions. Our goal is to inspire the end customer, whilst providing support and service, and passing our innovations and technical knowledge onto the partner.”

For Vetipak, the flexibility of the new lines was key. The company particularly wanted to make easy changeovers to different packaging formats, lowering the entry barriers for technical solutions. Van De Weghe adds: “Vetipak has added another 17 new robots to their installed base together with Omron Robotics Integrated Controllers.

“Vetipak’s investment is not tied only to producing confectionery retail packages or the assembly of luxury gift sets. The flexibility of the technology ensures that also future needs can met by reprogramming and repurposing the robots for new or other lines if necessary.”

Mark van der Burgt continues: “We have been very pleased with the solution and the collaboration. We want to contribute to the success of our customers by becoming a co-production partner as well as contract manufacturer, and provide them the benefit of the factory of the future.

“We believe that we can achieve the best results by developing solutions that involve people and technology working in harmony together, ensuring even greater flexibility, scalability, and quality. I’m sure that our partners B Electrical and Omron will continue to inspire us and share the latest knowledge with us to realise those goals.

Want the latest machine building news straight to your inbox? Become a MachineBuilding member for free today >>