Posted to News on 16th Dec 2020, 15:19

Visppro Robotic Solutions

Based in Bristol, Visppro is privately owned by Ben Cann and Roger Standing. The business specialises in automation projects from the smallest to the largest

Visppro is a machine builder and automation specialist, and has completed a number of large, medium sized and small automation projects for a variety of manufacturing companies from global brands at one end to small, niche manufacturing operations at the other.

Maximising the backgrounds of its two Principals in the field of machine and automation efficiency improvements, Visppro was initially established to provide industrial robotic solutions to help manufacturers improve their line Overall Equipment Effectiveness. Visppro says its business is small, carries low overheads and works engineer-to-engineer with customers. As a result it provides cost-efficient, bespoke solutions.

The company states that its focus is on delivering user friendly implementations of robots and robotic automation which are easy to use, flexible and provide an excellent ROI.

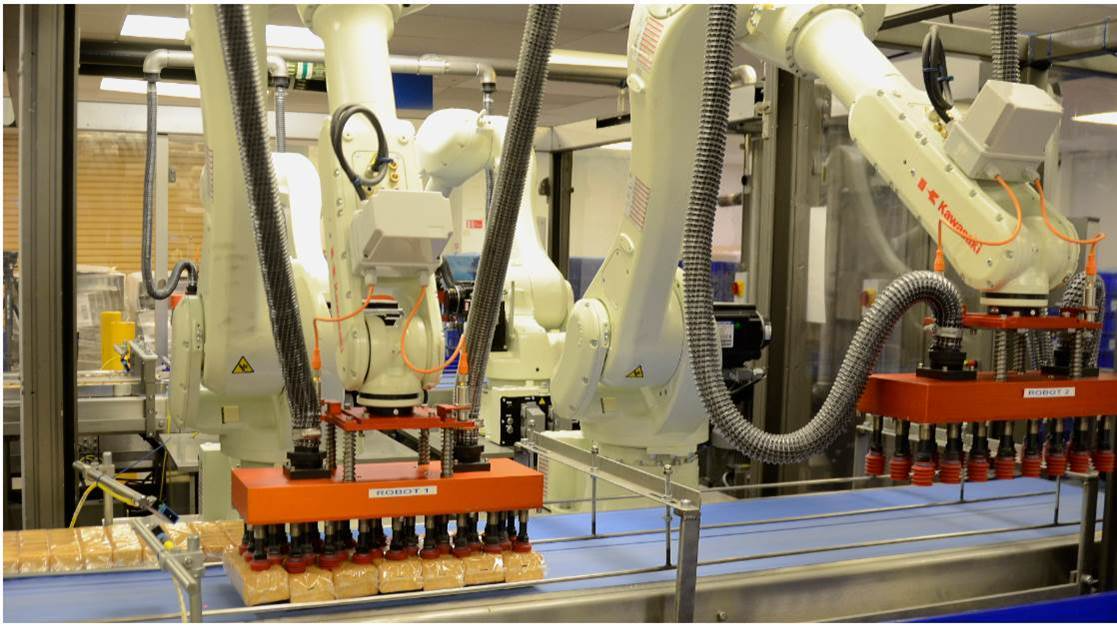

Recent applications have included CNC machine tending, the design and installation of high speed food packaging machines using both articulated and Delta robots, as well as palletising, welding stations and concrete product materials handling, the latter seeming to prove that they are hardened experts in the field.

Where possible Visppro will source ‘off-the-shelf’ component solutions as part of an ongoing commitment to cost-reduction for customers, and is keen to highlight its ability to design and install the best equipment and associated infrastructure that must always surround the installation of a robot. To this end the company can advise on product handling and collation, end effector reliability and efficiency as well as integration with other machinery and processes. Efficiency improvements, personnel safety and ease of maintenance and repair are other aspects in which Visppro says it specialises in order to deliver perfect-fit solutions.

Visppro can be contacted direct on 0117 961 6100.

Want the latest machine building news straight to your inbox? Become a MachineBuilding member for free today >>