Posted to News on 1st Aug 2019, 15:43

What are the options for AGV navigation sensors?

Various technologies are available on the market for bringing an automated guided vehicle (AGV) to its destination. Let us first of all say: many roads lead to Rome. There is no right way and no wrong way. Decisive is always the application itself - that means the question of where and how the given AGV is used.

There are different processes and technologies for navigating an AGV from point A to point B. The various possibilities range from contour navigation (natural navigation) to laser radar, optical or inductive guidance to grid navigation. Which technology is used depends above all on the specific application. The price of the AGV itself can also be used as a rough guideline. The costs for the navigation technology should not exceed 5 per cent of the AGV price. For example: for a EUR 10,000 AGV, contour navigation and laser radar do not come into question as their cost lies above the threshold of 500 euro. Another decisive criterion for one or the other variant is whether the given AGV is a drive-under vehicle or a platform vehicle. Drive-under vehicles are those that move under the load to be transported and lift it up. Their design makes them unsuitable for, e.g., laser radar, fundamentally excluding this process for such AGVs. Platform vehicles are those onto which the load is pushed and that transport their cargo on the vehicle. Against this background, the individual navigation possibilities are considered in detail below with regard to their possible fields of application.

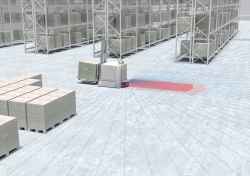

Contour navigation (natural navigation)

Contour navigation is also referred to as "natural navigation". These are the most technically complex as well as the most expensive types of navigation systems. They are unmatched in terms of flexibility and accuracy. Should it be necessary to change the transportation path on short notice, this can be performed for contour navigation very easily and quickly at the click of a mouse in the higher-level software, the so-called fleet management. Because the sensor on the AGV is usually mounted close to the floor, this navigation variant is suitable for automatic high-lift trucks and tractors as well as for the drive-under or platform vehicles described above. For this type of navigation, neither further tools - such as reflectors or optical or magnetic traces - nor markings or codes are required.

Laser radar

Navigation by means of laser radar is similar in flexibility to contour navigation. This navigation variant does, however, always require an additional optical connection of the sensor to the reflectors. Each sensor must therefore be mounted high enough on the AGV that it always has a clear view of the reflectors. If the connection to the reflectors is interrupted, e.g., when entering a shelf aisle, the AGV must switch to another type of navigation. This makes it more difficult to change to another room if necessary, limiting the flexibility.

Optical and inductive guidance

Optical and inductive guidance are usually very simple systems that follow a predefined trace. As a result, they are very limited in terms of flexibility. On the other hand, however, they represent a very cost-optimised solution. Because the sensor on the AGV is mounted only a short distance from the floor, such a form of navigation is independent of the selected vehicle type.

Grid navigation

With the so-called grid navigation, information is embedded in a specified grid on or in the surface that is travelled, e.g., 2D-codes or transponders. With the help of the information ascertained while travelling over the individual grid points - with a 2D-code these are, e.g., the code information and reading angle - the AGV can navigate between the individual grid points and thereby reach any specified point within the grid. This type of navigation is suitable above all for clean surfaces and surfaces not subject to heavy loading.

A general evaluation and recommendation for the suitable navigation variant can only be determined in combination with the function of the AGV within the given application. At the present time, however, there is a clear trend towards contour navigation with integrated safety function.

Learn more at www.leuze.co.uk.

Want the latest machine building news straight to your inbox? Become a MachineBuilding member for free today >>

1B Fenice Court

Phoenix Park

Eaton Socon

PE19 8EW

UNITED KINGDOM

+44 (0)1480 408500