Posted to News on 3rd Jan 2024, 10:49

What’s new at Mechan Controls?

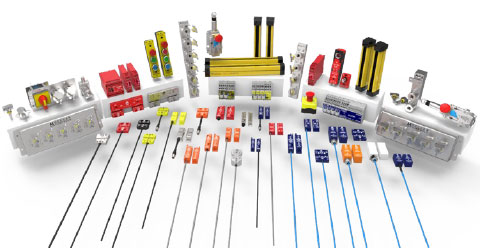

Through continuous innovation and research over the past 51 years, with over 100 years of experience within the machine guarding safety industry, Mechan Controls is now launching a number of new safety products, including new Grabwire safety switches, a simple and effective trapped key system and a tag-in, tag-out system.

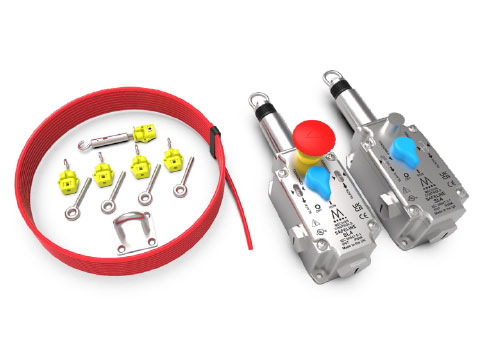

The new range of Grabwire safety switches fulfil the requirements of any machines where physical guarding is not possible. Made to the highest quality standard, Mechan Controls says the SafeLine 4 Grabwire is the future of conveyor guarding.

Made from 316 stainless steel and IP69k rated, the SL4 can withstand the harshest of environments and cleaning procedures. With a cable span of up to 75 meters, the SL4 can offer protection over a vast working area, keeping all users safe.

Dual tension indication makes the SL4 visible from most angles whilst tensioning. A blue reset switch and an optional mushroom E|Stop make the SL4 suitable for most applications.

The SL4 will come with either 2 normally closed and 2 normally open contacts, or 3 normally closed and 1 normally open. This comes with a positive mode mechanism that ensures the contacts are immediately latched open on actuation and can only be reset by turning the blue reset switch.

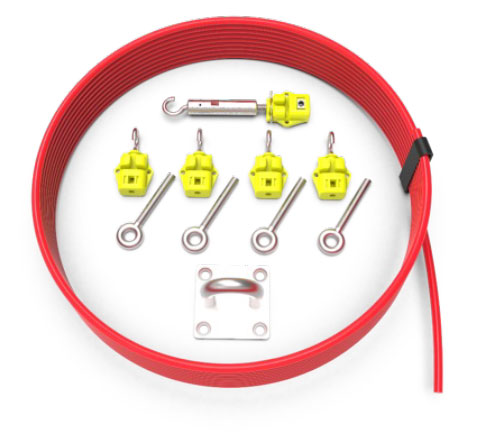

Mechan Controls will provide its very own tensioning kit, which will include:

Up to 75 Meters of rope.

Stainless steel turnbuckle kit.

Cable clamps for ease of installation.

Eyebolts.

Anchor plate.

The SL4 conforms to all relative safety standards including ISO13850 and IEC60947-5-5.

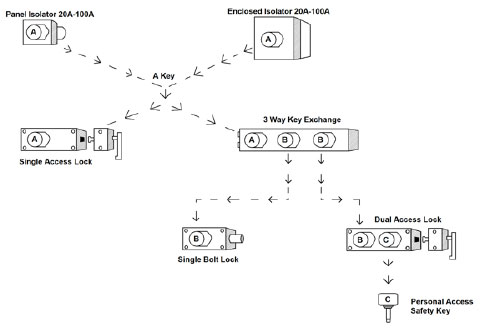

MK-Safe key exchange

Mechan products provide improved increased safety and efficiency within plant engineering. Creating intelligent networked systems is the key to a sustainable future. The vision of new machine guarding safety products will open new possibilities that will improve and refine the productivity of its customers.

The company is proud, therefore, to introduce a new range of mechanical machine guarding safety products, the MK-Safe range. This is a trapped key system that is simple and effective, providing high levels of security with the simplicity of key transferring and machine segregation to protect its operators.

Imperium control station

Much like the MK-Safe key exchange system, the Imperium tag-in, tag-out safety system is an electronic version of the key exchange system but without the physical or mechanical need to use a key.

An example of this might be four users operating a machine, where each one has a job to do when the machine has stopped. Each user has an RFID key fob. The designated machine can be stopped in three ways (depending on the button configuration):

1. Pressing the E-Stop button

2. Pressing the Stop button

3. Presenting and removing the fob key to the RFID module to tag into the designated area

When the machine is stopped by any of the three means above, each user entering the machine must present and release their fob key to the RFID module on the Imperium control station. Once the fob key is released from the RFID module, it will flash red to indicate that the user has registered and entered the area, then a solid red light will show to indicate a user is in the hazardous area.

Once all users have tagged in' and completed their tasks, they must then tag out'. Presenting and releasing each individual user's key fob to the RFID module when leaving the machine will cause the RFID module to flash green then hold solid red if another user is still tagged in the system. Once all users have tagged out' the RFID module will hold a solid green, indicating that the machine is now able to be restarted.

If the power to the Imperium is lost when a user(s) is tagged in, the system will then retain the stored fobs when the power is restored.

In the eventuality that a user goes home with a fob key or loses it and has not tagged out' of the system, a master key fob can be used to override the system. When the master key fob is presented to an Imperium system that still has a user tagged in, the RFID module will flash red at a different frequency to indicate that a user is still within the hazardous area.

Once the manager or supervisor has performed their checks to declare that the machine is safe to be restarted, they will present their master key fob a second time to the RFID module. In doing this it will clear the Imperium's memory of any stored tags and the machine can be restarted.

If a master key fob has been lost or damaged, the power must be cycled from 24V DC to 17V DC. A new fob is then presented when the supply is at 17V DC and the RFID module will go from flashing purple to solid purple, indicating that a new master key fob has been taught.

Want the latest machine building news straight to your inbox? Become a MachineBuilding member for free today >>

14/16 Seddon Place

Stanley Industrial Estate

WN8 8EB

UNITED KINGDOM

+44 (0)1695 722264