Posted to News on 6th Sep 2007, 17:31

Wyko joins Eriks group and targets OEM and MRO markets

Wyko was acquired by Eriks in November 2006 for £139 million. The combination of the two companies offers an enormous breadth and depth of products and service know-how to the OEM (original equipment manufacturer) and MRO (maintenance, repair and operations/overhaul) markets. A new slogan, That's a big plus, is being used to promote a campaign to explain the benefits to Wyko' and Eriks' customers.

Eriks claims that its acquisition of Wyko makes the Eriks group the clear market leader in the industrial equipment distribution business in Central and Western Europe, with sales of EUR850 million and approaching 4500 staff. The Eriks Group now operates 218 service centres and 62 production and technical centres with a product range of over half a million items.

Wyko intends to establish itself as among the top three companies in each of its eight chosen core activities:

- sealing technology

- power transmissions

- flow technology (fluid handling)

- industrial plastics

- tools and maintenance products

- technical and logistics services

- electrical and mechanical engineering services

- specialist technologies

What differentiates Wyko within the industry is that it is an innovative supplier that delivers both products and engineering know-how to its customers, adding a great deal of value to their business. Consequently the company should be viewed as an industrial service provider, rather than a traditional parts distributor.

Having acquired Wyko, the Eriks group is in a very strong position to operate its twin business model in which OEM and MRO markets are serviced from a common logistics core. It is now able to meet the needs of these two major customer bases through Wyko's single business infrastructure and team. For the MRO market the company offers engineered solutions with a wide range of products via flexible supply channels. For the OEM market the company offers min-depth anufacturing know-how with value engineering delivered via dedicated channels.

One of the ways Wyko helps its customers is by using its market know-how to help counteract adjustments in the way customers' businesses have to work as a result of changes in legislation, tax, and other commercial forces. The Wyko team can provide advice, then instigate and deliver products and services to help the customer deal with such events. A good example of this has been Wyko's proactive approach to the climate change levy (CCL) and rising fuel costs, where its range of technologies and its ability to offer advice and practical assistance has helped a myriad of customers lower their energy bills.

In addition to the increased product range, the main benefits to customers of doing business with Wyko are best summed up in the know-how domains that form the core business values:

Market know-how – being close to its customers enables Wyko to benefit from feedback and be the first to market with new technologies and services, thereby meeting industry's ever-changing demands.

Product know-how - Wyko possess in-depth technical and commercial knowledge of its products and their properties. This is conveyed via different types of technical documentation, electronic resources and in-person to customers. All of this key information is available 24 hours a day, seven days a week.

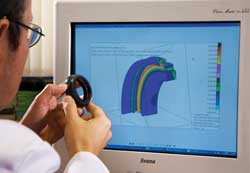

Application know-how – Wyko is able to understand current applications and help develop its customers' future conceptual requirements, then engineer them into practical products. Wyko is also able to address reliability and cost issues facing customers and optimise designs or offer alternative product (product development). Wyko likes to brainstorm with customers in the design and maintenance of new products and systems (research and development).

Customisation know-how – Wyko is able to translate customers' concepts into new product specifications and then supply these products from its own in-house production or from specialist partners. It also has its own maintenance/repair facilities and services for the broader range of components and systems supplied by Eriks or others.

Logistics know-how – Wyko is able to analyse and streamline logistic flows to match customers' demand patterns. Logistics are quickly and simply tailored to interlink with customers (all the way from identification of the customers' needs, through to payment), both for the administrative side and the physical part flow. From simple component supply through to fully integrated solutions and VMI (vendor managed inventory) on customer facilities, Wyko makes procurement more efficient for its customers

Infrastructure know-how - Wyko has highly optimised and modern logistics to ensure its customers get what they need when they actually need it. Its maintenance and production facilities are efficiently structured and staffed by experienced specialists. The modern bespoke IT system supports the Eriks team to deliver value to customers' business.

Using this know-how, Wyko also excels in advising its customers when to repair a product or item of equipment, and when to replace it. In the first instance, Wyko always looks to work with the customer in providing predictive maintenance to prevent problems happening in the first place. However, where this has not been possible, Wyko is often presented with queries from customers as to the best way to solve a particular problem. For example, a piece of machinery has failed and the customer wants to know whether to purchase a new part, at what cost and what the lead time is going to be. They also want to know what the comparable cost of performing a repair may be, plus how long it will take and how long that repair will last. The customer wants all the variables in order to make the best decision. The combination of electromechanical service specialisation and a product range of more than 500,000 items means that with Wyko, now an Eriks company, customers can get it all from one place.

Since April 2007 staff have been answering the telephone with the phrase, "Hello, Wyko, an Eriks company", but the plan is to phase out the Wyko name by March 2008. Between September 2007 and March 2008 all of the service centres and workshops in the UK will be redesigned and rebranded. In addition, regional events will be held in 2008 to further educate customers.

Want the latest machine building news straight to your inbox? Become a MachineBuilding member for free today >>