Posted to News on 15th Sep 2014, 18:48

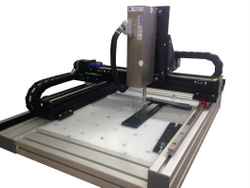

XYZR gantry scanning system design and build by LG Motion

A novel motorised XYZR gantry scanning system with a combined vertical and rotary positioning axis that includes the ability to measure its force, position and velocity has been supplied to the Imperial College Non-Destructive Evaluation Group by LG Motion for a research project to evaluate critical aspects of a high-temperature strain-monitoring technique for use in power station steam lines and associated components.

The technique, which allows continuous on-site monitoring of the integrity of the components rather than the previous method which relied on laborious microstructural assessment during often infrequent outage periods, involves measuring the electrical resistance between electrodes permanently attached to the component surface. As the component deforms the electrodes separate and a change in the resistance is observed.

LG Motion's gantry scanner is being used in the laboratory as part of a test rig that focuses on the technique's sensitivity to changes in the electrical conductivity of components that are caused, for instance, by the influence of microstructural changes associated with power station creep damage, such as grain boundary separation and carbide evolution.

The specification for the scanning system was drawn up after engineering sales visits to the Non-Destructive Evaluation Group's facilities and subsequent information exchanges that included LG Motion design engineers drawing up proposals to ensure the requirements could be met within the limited space available for the rig. This identified the main requirements for a horizontal scanning area of 200mm x 200mm with a 10mm vertical travel and rotation that would be used to move and accurately position a small probe assembly on the surface of various components that had been subjected to microstructural damage.

With the ability, through a supplied LabVIEW-compatible motion control system, to combine the positional, velocity and force information from the vertical/rotary axes with the resistance measurements from the probe, as well as control the X and Y axes in the same system, a complete evaluation was made possible with the minimal number of components - thereby simplifying installation and saving time and cost.

Moving coil actuators

The combined linear and rotary axis for the scanning system is part of a wide range of moving coil actuators from LG Motion's distribution partner SMAC Europe Ltd. This motion technology is available in linear, rotary and linear/rotary motor formats and allows very fine programmable control of speed, position, force and torque for a wide range of automation, measurement and inspection applications. With its 'soft land' function, which allows the force to be finely controlled, SMAC actuators are used for performing very sensitive work in industrial applications such as fine thread forming or precision torque tightening for very small components, as well as the critical components in pick-and-place systems for handling delicate materials.

Through its design and production capability, LG Motion combined the SMAC actuator with low-cost lead screw-driven linear slides from its BiSlide range for the X and Y axes, arranged as a lower Y-axis with a parallel linear rail bearing supporting the single X-axis. The BiSlides include microstepping motors with hand-wheels fitted to aid manual pre-setup of the scanner.

The complete fully tested assembly features chain-type cable-management and was supplied on a MiniTec extruded aluminium machine frame with a fully wired control cabinet including drives and controls for all axes in accordance with BS EN 60204-1 that covers EMC and LVD requirements. The SMAC linear/rotary positioner was also fitted to the assembly to facilitate its quick removal for use independently for other work required by the Imperial College Non-Destructive Evaluation Group.

Go to www.lg-motion.co.uk to learn more about the novel motorised XYZR gantry scanning system and LG Motion's capability for designing and manufacturing specialist motion control systems.